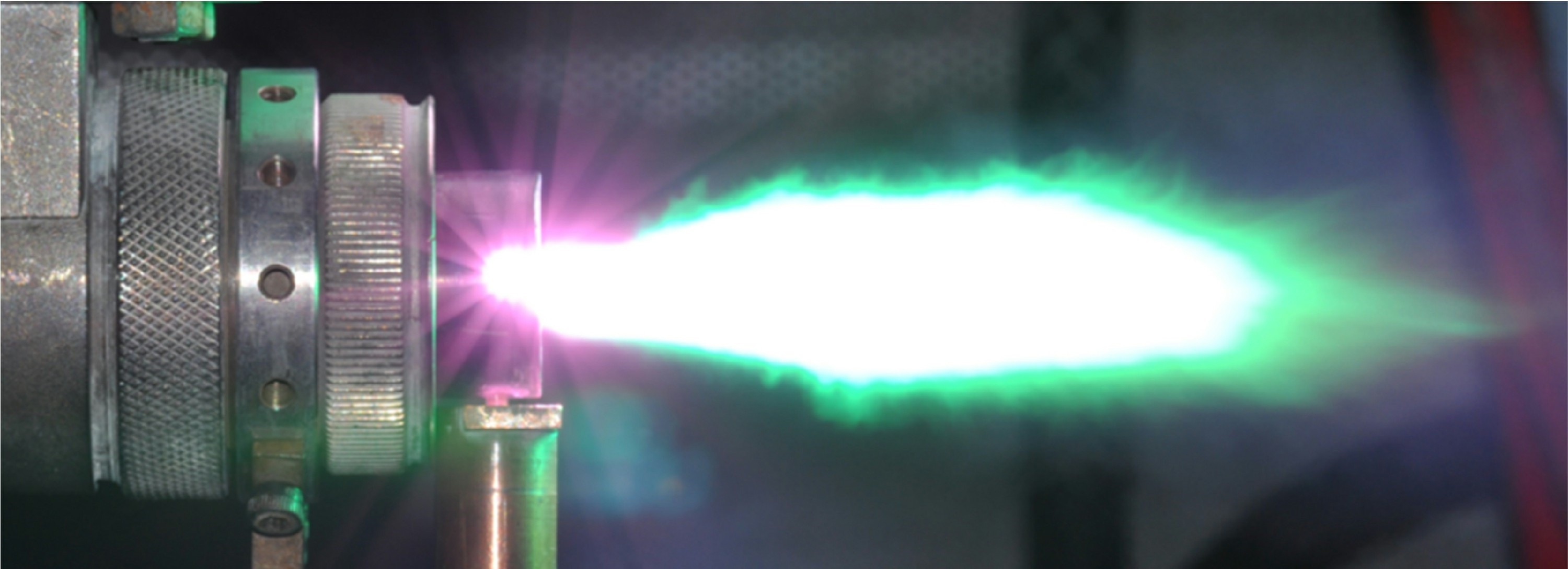

Drying of a Single Suspension Droplet in Suspension Plasma Spray

- Morteza Javid

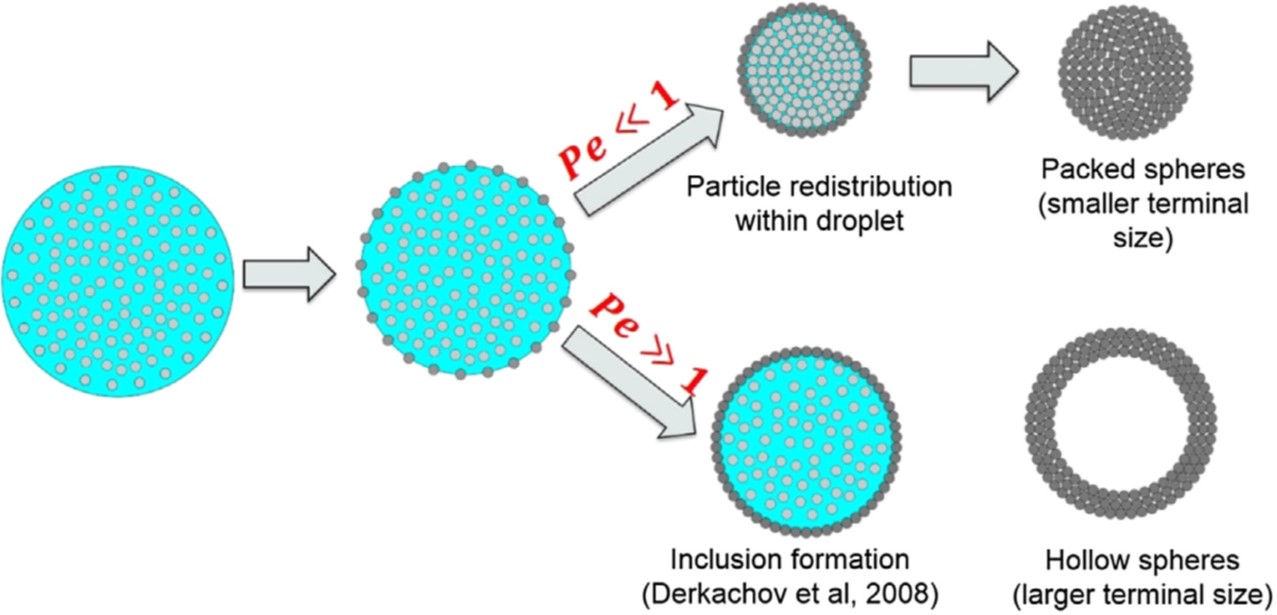

Compared to a monocomponent droplet, the evaporation of a suspension droplet is more complicated due to existence of particles inside the droplet which significantly changes the apparent properties of the liquid, e.g., viscosity and surface tension. Drying suspension droplets exhibit unique behavior, which is a combination of liquid and elastic matter, and accurate numerical modeling of such analytical description poses a great challenge. This research focused on developing unique numerical models for drying of suspension droplet in high rate evaporation processes. The developed Eulerian-Lagrangian models can describe consecutive states of the complicated process, including droplet shrinkage, particle accumulation on droplet surface, and droplet buckling as reported in literature. The numerical results reveal that the role of capillary forces in the shape of agglomerated particles is significant. It is found that particle-induced surface pressure drives the buckling of the suspension droplet. It is also shown that the particle-induced surface pressure reaches a threshold value at the onset of buckling and overcomes surface tension. The models have been validated by comparing the simulation results with designed experiments. The numerical results are in good agreement with the experimental ones, both qualitatively and quantitatively. Green-SEAM, an NSERC strategic network, supported this work.

Evaporation-driven agglomeration of particles when Pe << 1 (Pe ~ 0.0022)

Animation of agglomeration of particles during buckling of the droplet.

Droplet diameter: 20 µm, containing 5000 600 nm YSZ particles, Stiffness parameter: 0.4? Pe = 1.16×10E5