Drop Impact on Narrow Gaps

- Jordan Bouchard

Many engineering applications involve liquid drops impacting on a porous surface. Examples include spray painting wood, application of herbicides of crops, or additive manufacturing. In some applications it is important to control how much the drop spreads on the surface and how deeply it penetrates the substrate. Increasing the velocity that the drop impacts the surface could conceptually provide more energy for deeper penetration, but it also will increase the tendency for the drop to spread on the surface. Unfortunately, we are unable to observe inside conventional materials while the drop is impacting, so we have a limited understanding on how the impact velocity and the size of the pores affect the penetration of a drop into porous materials.

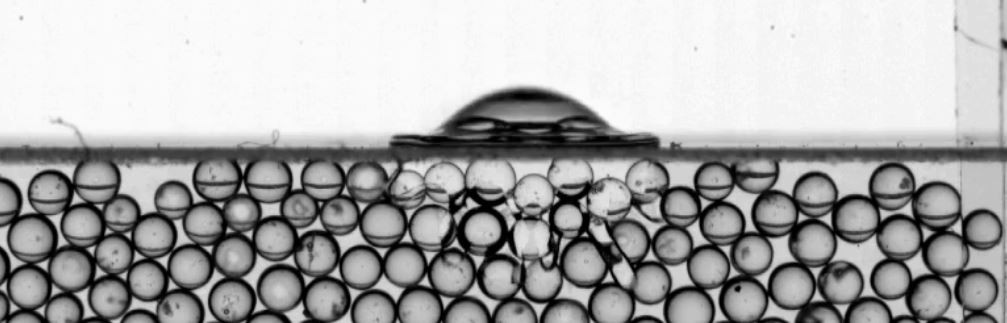

We approached this problem by first considering a simple pore, a long narrow gap constructed between two panes of glass. By using glass, we can simultaneously observe the drop spreading over the surface and penetrating the gap. The results show that the energy from a droplet impact is expended in less than 2 milliseconds after the drop strikes the surface. Drops penetrate further into larger gaps then smaller gaps because larger gaps resist the flow to a lesser extent. Also, since more of the drop enters the gap, drops impacting larger gaps tend to spread less than drops impacting smaller gaps.

Penetration of a 2.0 mm water droplet into a 50, 100, and 150-micron gap between two parallel glass plates. Constant impact velocity of 1.0 m/s.

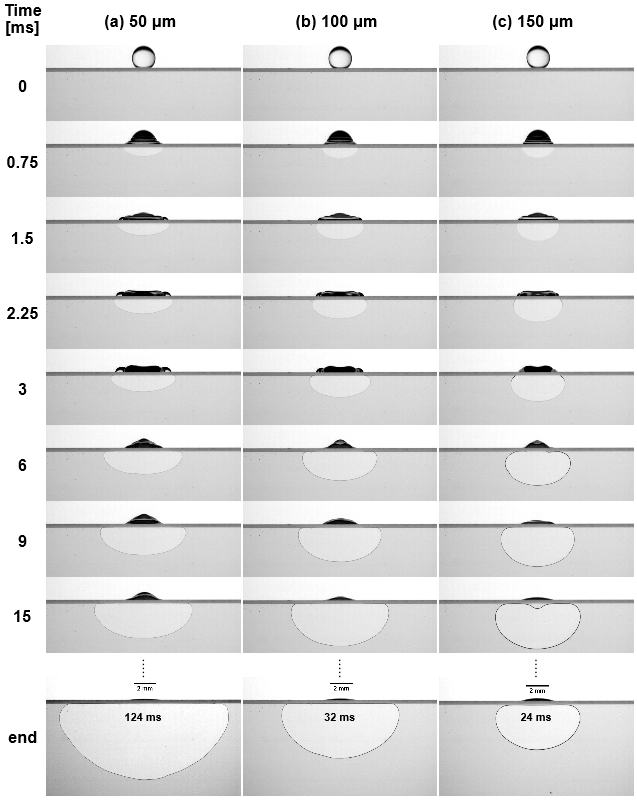

However, in engineering there are usually trade-offs that need to be considered when designing a system, and this experiment was no exception. Increasing the impact velocity will increase the penetration depth of the drop into the gap, but it will also lead to drop cleaving. Drop cleaving is when a drop strikes a pore with enough force that it separates into two halves. Only the liquid in the drop that was directly above the pore prior to impact can flow into the pore, and the rest of the drop remains on the surface of the material. The trade-off becomes balancing the depth of penetration with the volume of liquid that enters the pore.

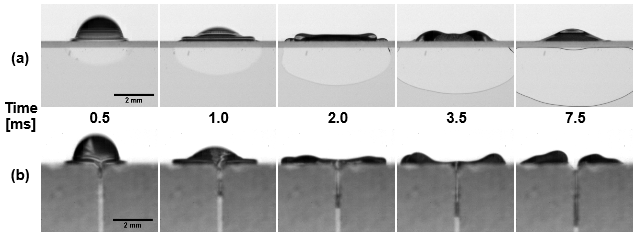

2 mm drop impacting a 100-micron gap spacing at 1.5 m/s—front view (a), side view (b). The indicated time is the time measured from droplet impact. The drop stops flowing in the the gap because the drop has been cleaved into two halves.

Drop Impact on Narrow Gap

Droplet Cleaving