Fast and High-Throughput Synthesis of High-Entropy Alloys using Radio-Frequency Inductively Coupled Plasma

- Morteza Javid

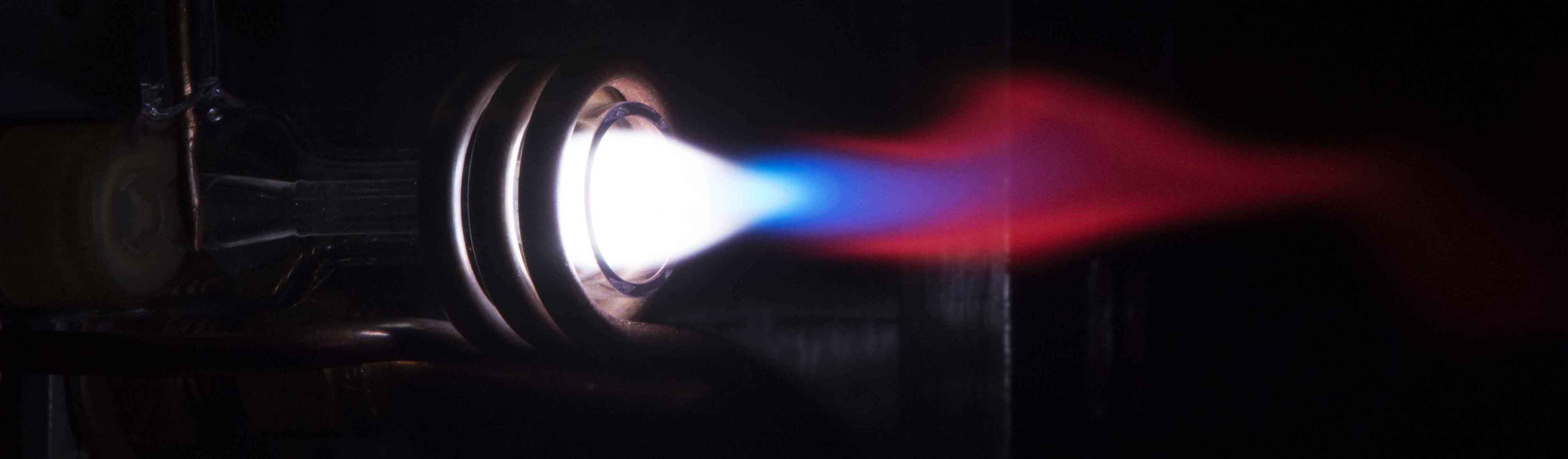

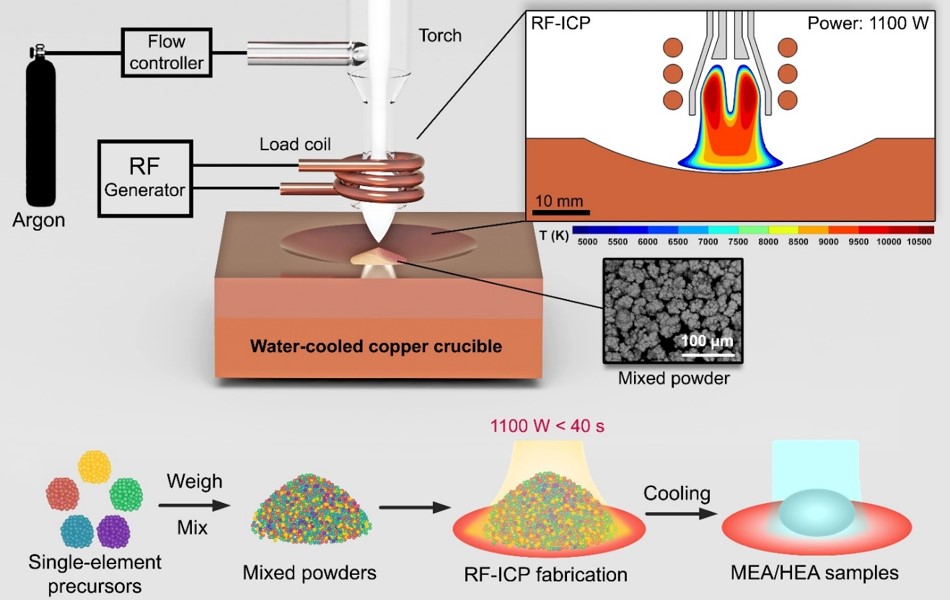

A rapid manufacturing technique for high entropy alloys (HEA) has been developed. These alloys are currently the subject of intense research for their superior properties. Radio-frequency inductively coupled plasma (RF-ICP) has been employed to synthesize the different HEAs. RF-ICP provides a plasma source, in which RF current is passed through a load coil to generate an intense electromagnetic field inside the torch and ionize the gas. Similar to the arc melting, such a technique features an extremely high processing temperature (up to 5000–8000 K) and heating/cooling rates up to 105 K/s providing a high-efficiency alternative for MEA/HEA synthesis.

This method features a high fabrication speed (< 40 s) preventing the material from volatile evaporation, reduction of the non-uniform distribution of microstructures caused by uneven diffusion due to high heating rate, eco-friendly heat source without the emission of harmful gases or secondary products to the environment, elimination of the unstable impurities, improved controllability of the process in comparison with the free burning arc due to the absence of arc instability, minimization of the contamination of the synthesized samples from electrode erosion due to electrodeless design of the RF-ICP, formation of a natural shroud gas around the sample by the plasma jet minimizing the entrainment of the surrounding air, and use of any kind of precursor in different physical forms or chemical compositions. Therefore, this method provides a new opportunity to accelerate the discovery of new complex alloys for a broad range of applications.

Setup of HEA synthesis with RF-ICP. Well-mixed powder bed is directly synthesized by RF-ICP under 1100W with 5000 – 8000 K and becomes HEAs within 40 s.

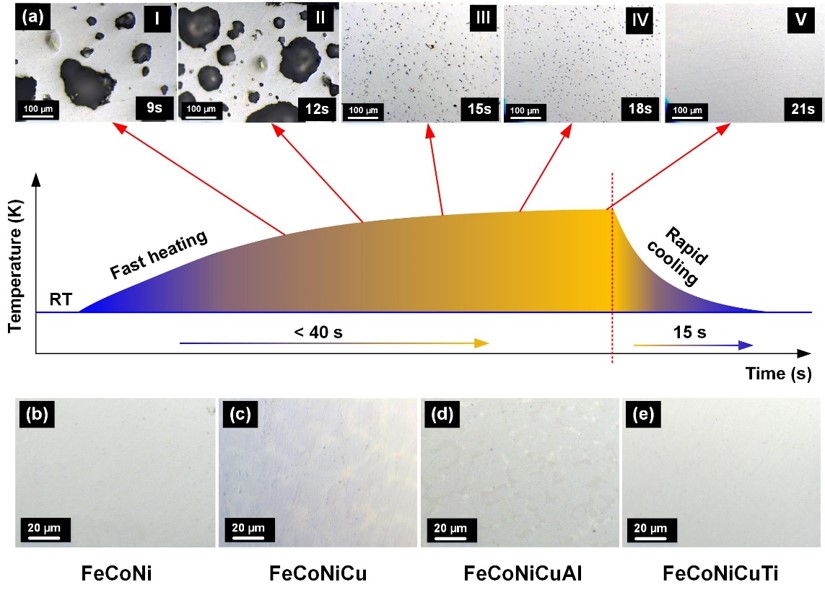

Rapid synthesis of alloys. (a) The temperature profile of CuNi alloy using the RF-ICP synthesis. The OM images demonstrate the evolution of porosity of CuNi alloy during HEA synthesis process. (b)-(e) OM images of synthesized FeCoNi MEA, FeCoNiCu MEA, FeCoNiCuAl HEA and FeCoNiCuTi HEA.