Thermal Spraying

The centre has a wide range of thermal spraying equipment as listed below. The photographs of some of these are also shown subsequently along with a suitable explanation:

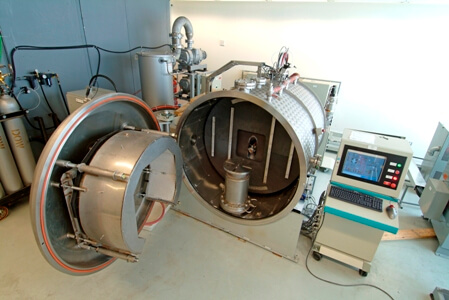

Vacuum Plasma Spray

The fully automated system is a combination of a furnace and a VPS system. Unique, 120 kVA vacuum plasma spray forming system. The chamber temperature (hence substrate) can be maintained at up to 800 C.

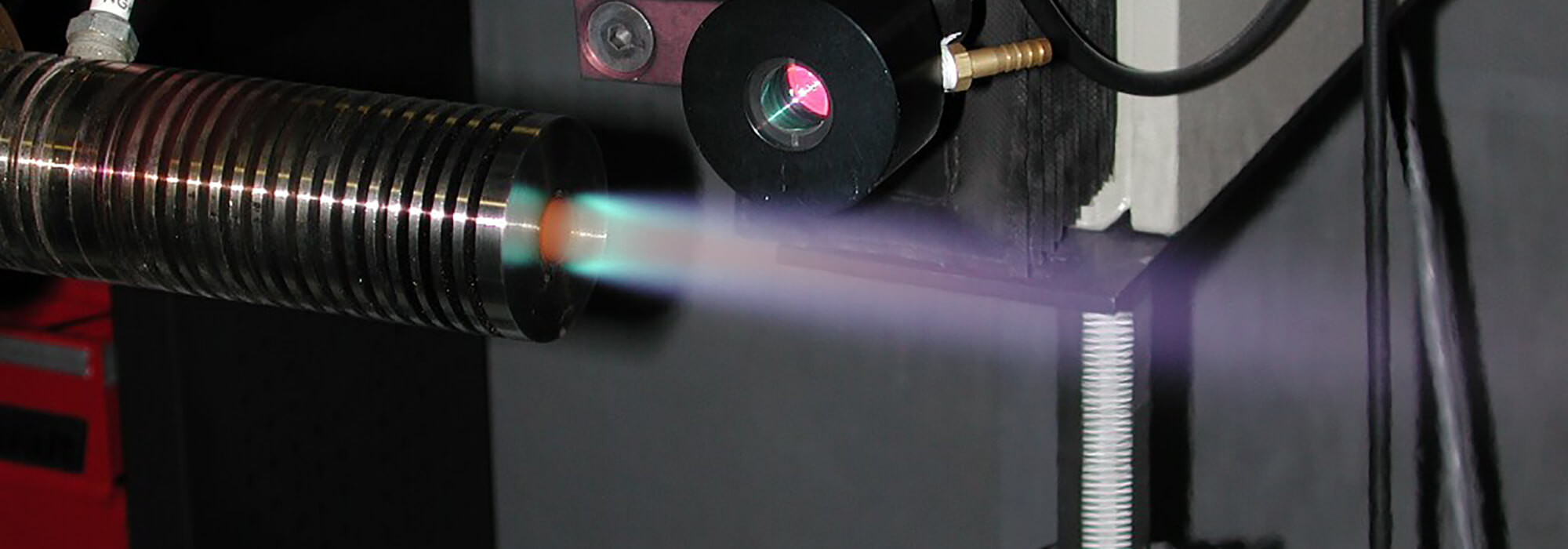

Hybrid DCP/RF-ICP Spray

The reactor includes a hybrid DC/RF-ICP torch issuing into a vacuum chamber that contains a computer driven 2-axis plus rotation substrate manipulator. Reactor pressure can be controlled and maintained at a selected level. The hybrid plasma torch has the advantages of both DC plasma and RF-ICP. More importantly, it does not suffer from the shortcomings of either technique. In the case of the RF-ICP, the problem of rapid cool down of the jet and the lack of heating along the axis is solved by introduction of the DC plasma jet.

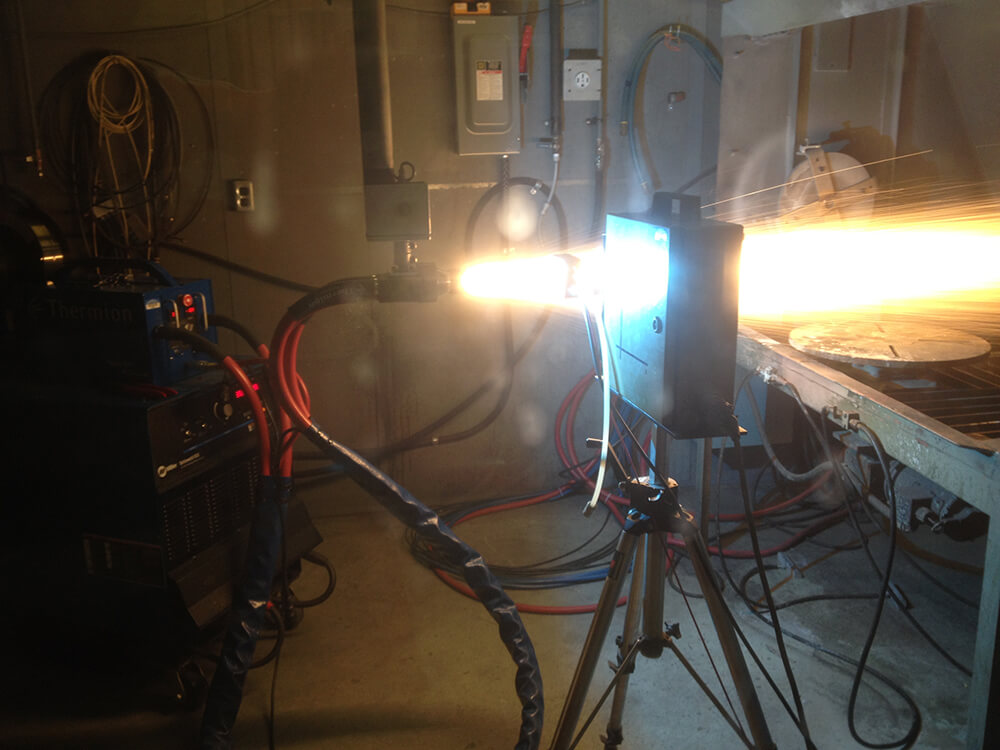

Thermion AVD 456HD Arc Spray

In the wire arc spraying process, electrical energy is used to create an arc that can heat and melt tips of two consumable wires, from which the molten materials are sprayed as a high temperature/high velocity flame. A cross flow stream of gas is also present to ease the detachment of the molten material from both cathode and anode. Spraying system that is being used in the lab is VALUARC 300 manufactured by Sulzer-Metco. The characterizing parameters of the process that define the state of coating are the material of the wire (Aluminum wires are mainly used), voltage that is applied on the wires (20 to 40V), wire feed rate (5 to 10 m/min), and pressure of the atomizing gas (30 to 70psi).

Atmospheric Plasma Spray

High-Velocity Oxy-Fuel (HVOF) Spray

The HVOF spray booth includes an Diamond Jet HVOF gun which is connected to a three degrees of freedom robot.