Thermal Spray Coating

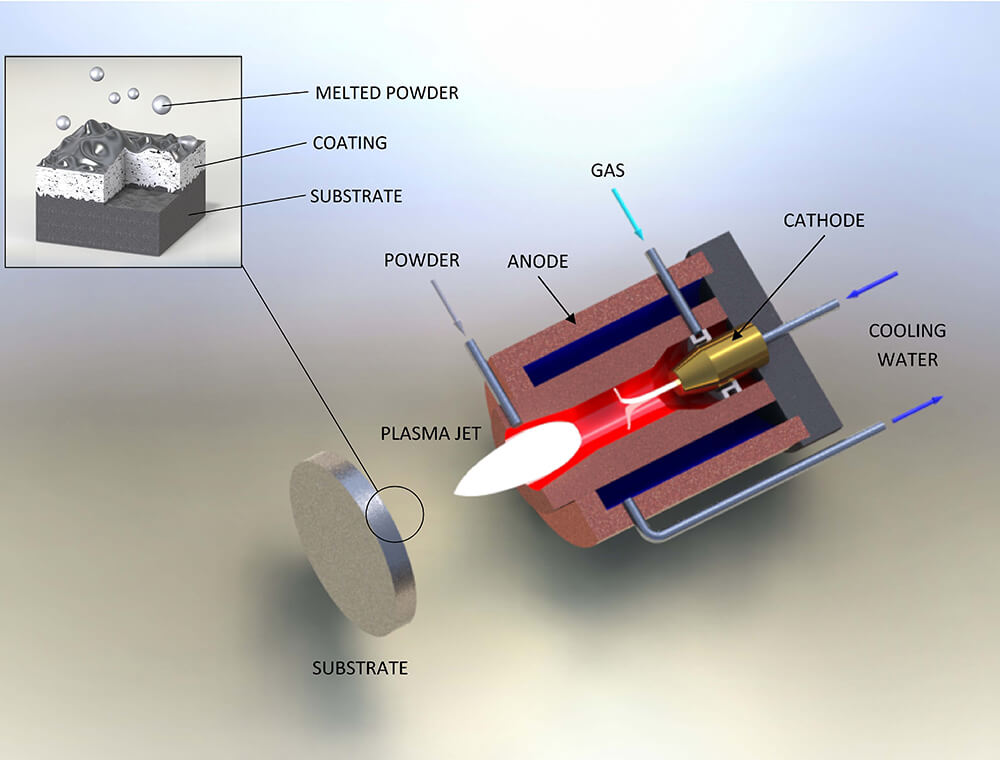

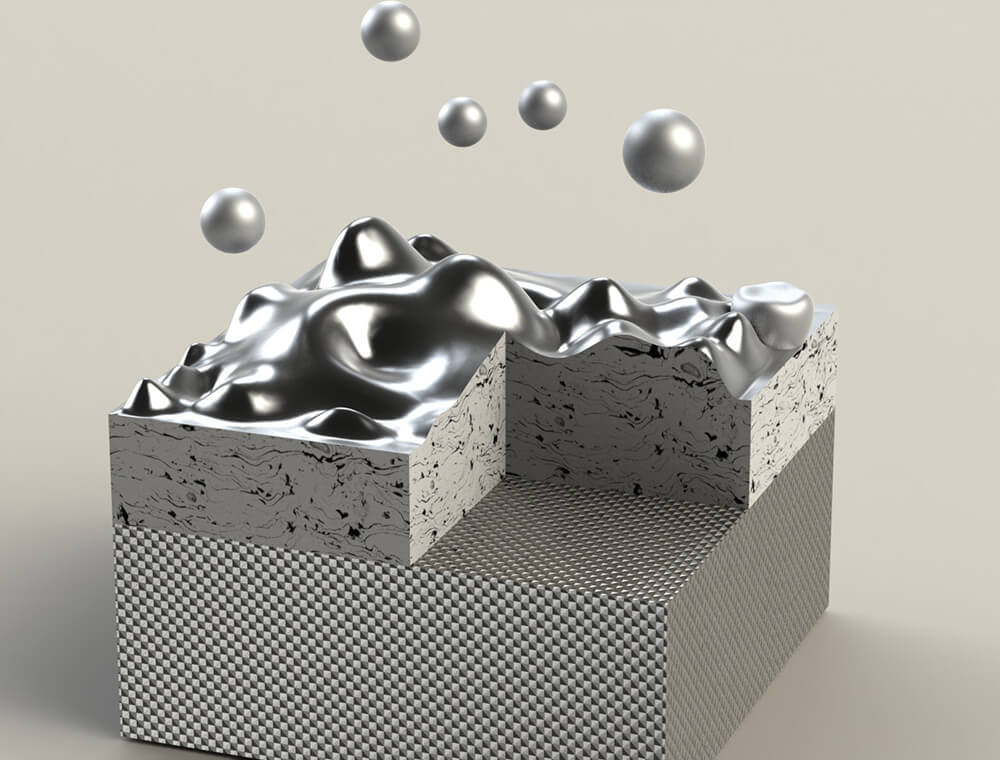

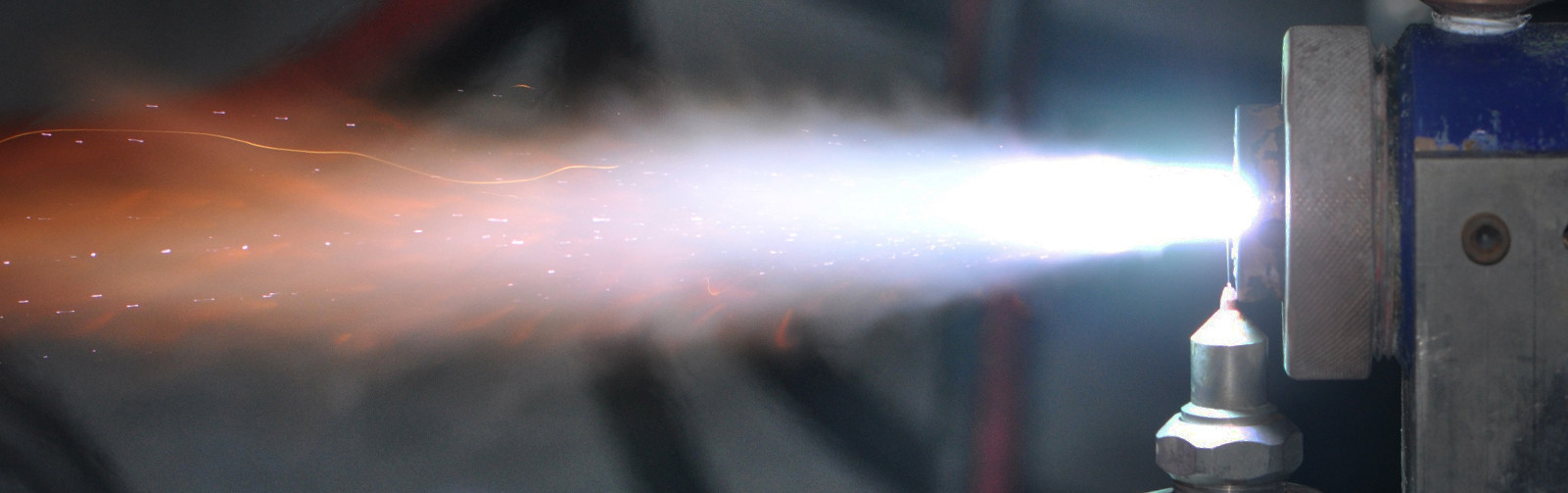

The engineering components in aerospace, automotive, power, chemical and other industries are frequently exposed to sever heat, abrasion, and corrosion. A thin surface coating of a suitable material such as ceramic or super-alloy is often the best way to protect an extend the life time of such components. Thermal spray coating technology is used extensively as an efficient, economical, and environmentally friendly method of applying coatings for a wide range of industrial applications. In an ideal thermal spray process, powder or wire shaped feedstock is fed into a high velocity, high temperature gas jet generated by an oxy-fuel combustion or an electric arc (plasma). Powder particles are melted and accelerated toward the substrate of mandrel mold. The in-flight particles have various temperature and velocity distributions upon impact. Finally, the droplets solidify after impacting the substrate. Solidification occurs at rates similar to those obtained in rapid solidification technology. Thus, the as-sprayed deposit is ultra-fine grained with a complex microstructure. Most metallic alloys, superalloys, cermets, and ceramic materials can be deposited using thermal spray techniques. Thermal spray deposits can be used in wear and corrosion protection, as well as in thermal barrier coatings for high temperature oxidation resistance applications. Thermal spray technologies give much higher deposition rates than other chemical or physical vapor deposition techniques, and the are more environmental friendly. These processes are capable of coating components varying in size from a few millimeters to several meters.