Sample Preparation and Manufacturing

CACT is equiped with several facilities for precision cutting, polishing, sand-blasting, pressing, 3D printing, etc.

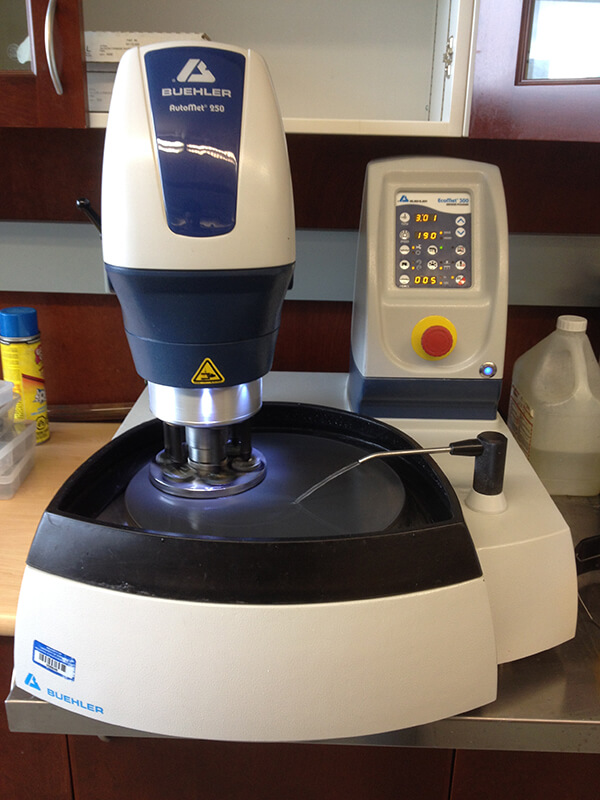

Buehler EcoMet 300 Grinder/Polisher with AutoMet 250 Power Head

The EcoMet is a 12” (305mm) heavy duty variable speed grinder‐polisher designed to prepare large and difficult to grind specimens. The AutoMet 250 Power Head upgrades the grinder-polisher from manual operation to semi‐automatic specimen preparation, increasing productivity and specimen consistency.

30 Ton Hydraulic Press

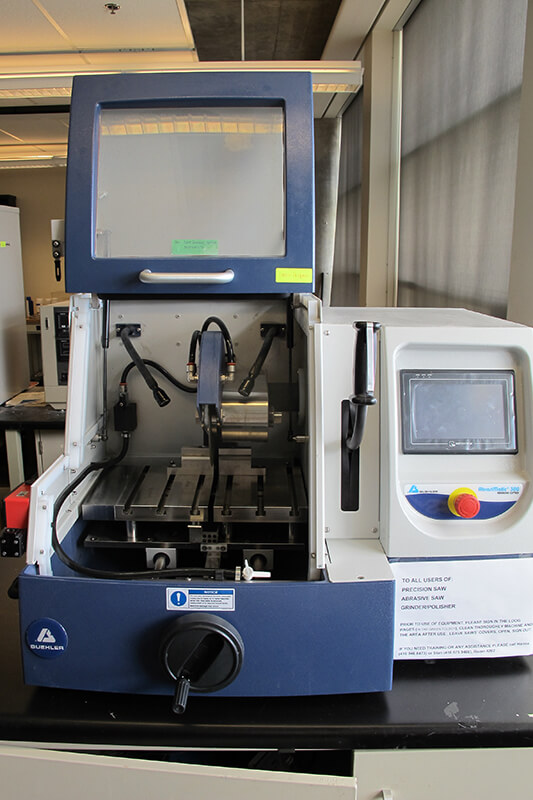

Buehler AbrasiMatic 300, Abrasive Cutter

This is a bench‐top cutter allowing for manual cutting in 2 directions or automated cutting in 1 direction. The large cutting chamber and wheel capacity can accommodate a variety of sample sizes. 12” (305mm) cut‐off wheel capacity can section up to a 4.375” (110mm) diameter sample of ferrous and non‐ferrous materials.

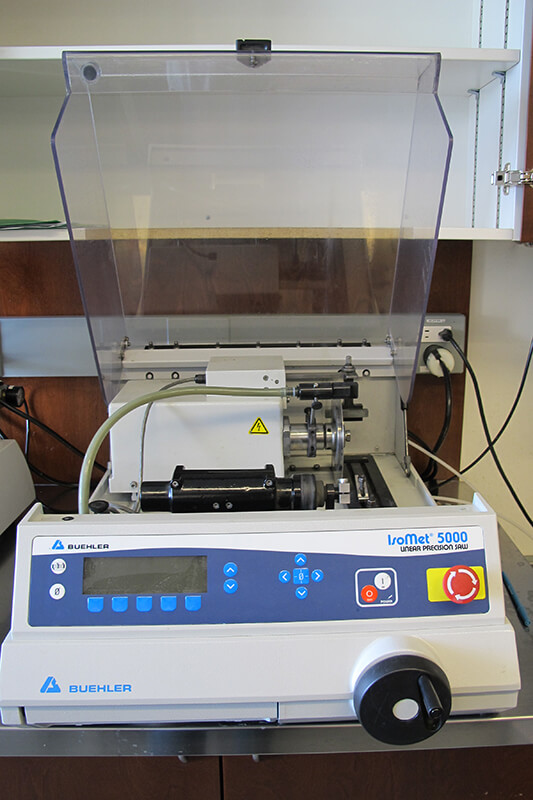

Buehler IsoMet 500 Linear Precision Saw

This automatic linear saw with SMARTCUT system, automatically adjusting the feed rate, and a 2μm Specimen Positioning System allows for precise cutting of delicate specimens without deformation.

35 preset Buehler methods provide sectioning parameters for a variety of materials including ferrous metals, non‐ferrous metals, ceramics, and geological spicimens.

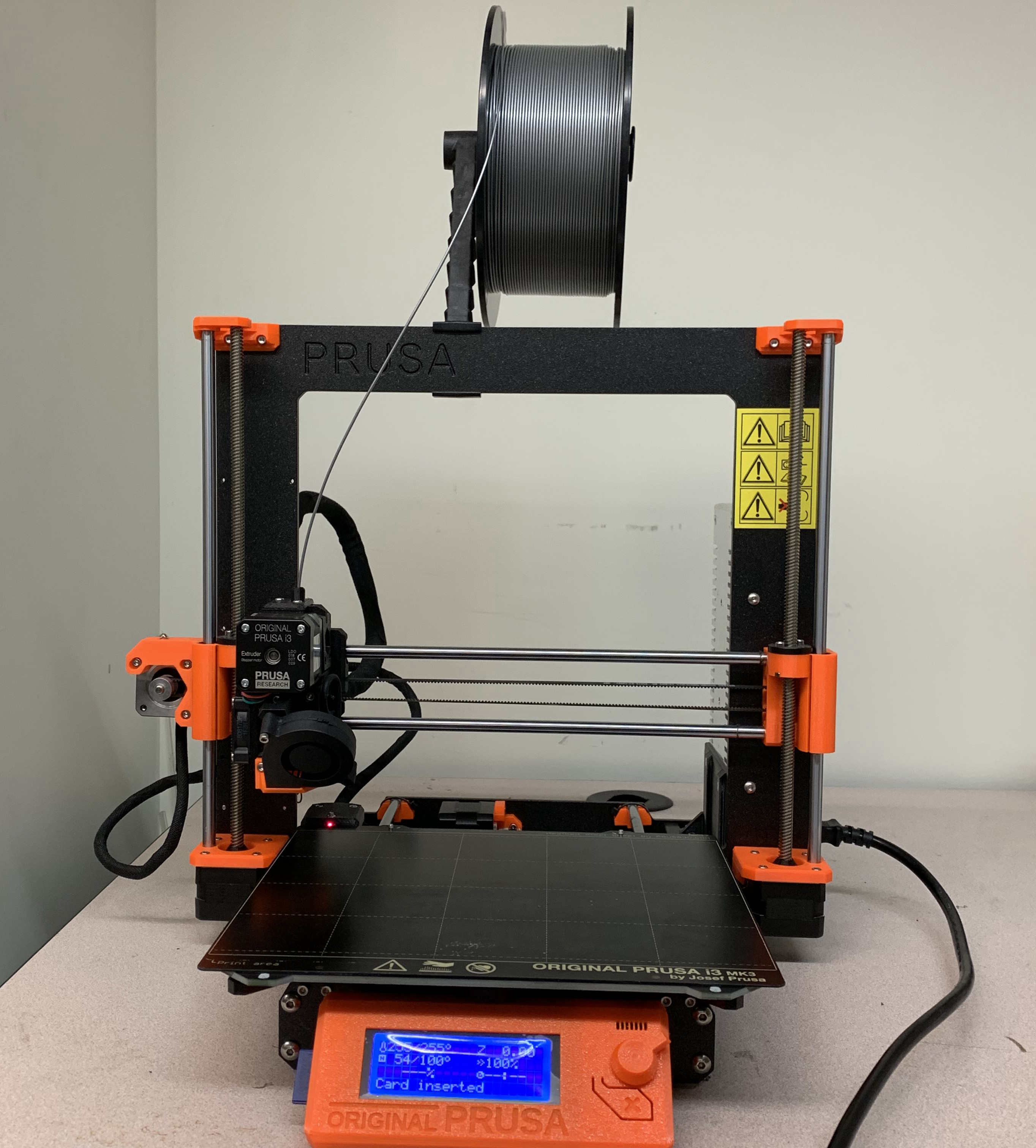

3D Printer

Prusa I3 MK3S 3D printer is capable of printing parts with dimensions up to 9.84 x 8.3 x 8 in. It is also capable of handling multiple materials like PLA, ABS, metal composites, carbon fill composites, and wood fill composites to detail of 0.05mm. The printer accompanied software Prusa Control accepts the 3D designs in a .stl format and generates a code transferable to an SD-card ready for an interface.

Econoline Abrasive Dry Blast System

Pressure pot dry blast system