Copper Alloy Coatings on Heat-Sensitive Materials

In addition to their versatile decorative finishes, copper alloy coatings have other functional properties too. Metals such as silver, copper and zinc have been demonstrated to effectively kill a range of bacteria including endospore-forming bacteria, within 10 – 120 min [1, 2]. Copper alloys are the most promising of these metals because of their availability, better corrosion resistance compared to zinc, and cost-effectiveness in comparison to silver. However, production of equipment or furniture with sheet metals has limited application due to their high cost and manufacturing challenges. Thermal spraying of surfaces with biocidal copper alloys could provide a cost-effective alternative, in addition to addressing a major health concern.

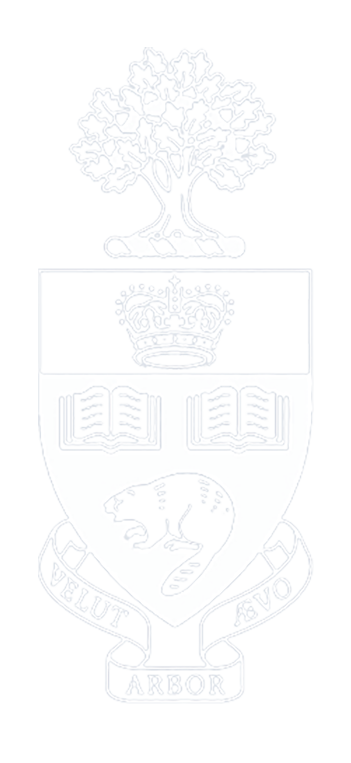

These metal coatings, in addition to making the wood surface more aesthetically appealing, are also able to protect the wood from moisture, ultraviolet radiation, and mildew. The other advantage of metal coatings in comparison with common organic coatings is that they contain zero volatile organic compounds (VOC) and do not require any drying time.

Figure 1. Examples of metal coated interior installations. (a) Carved mahogany ornament before and after copper coating, (b) MDF installation with different metal coatings, and (c) patinated copper coating on wood beams.

Coatings Adhesion

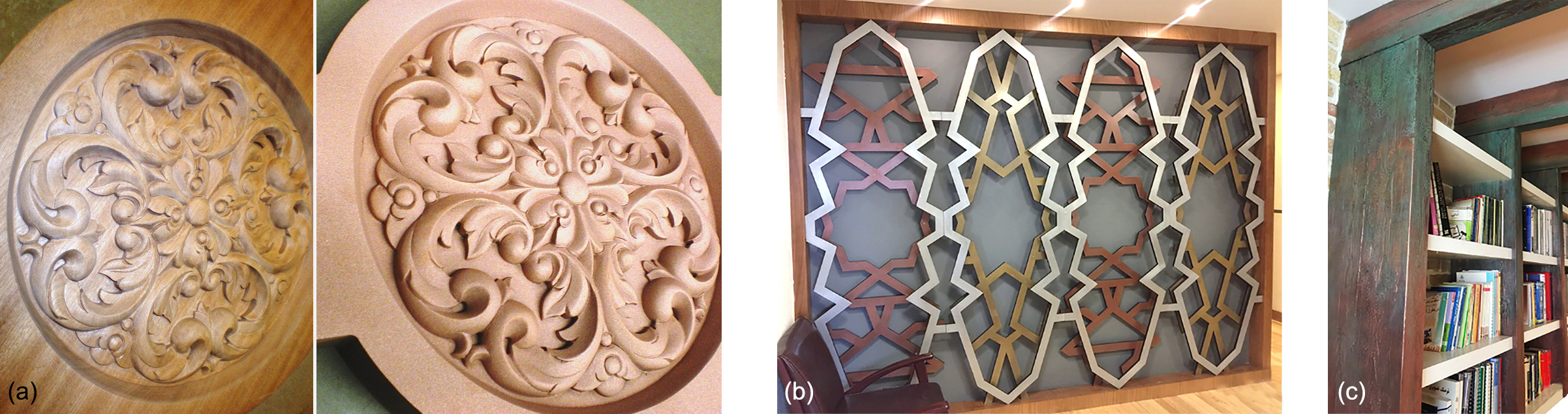

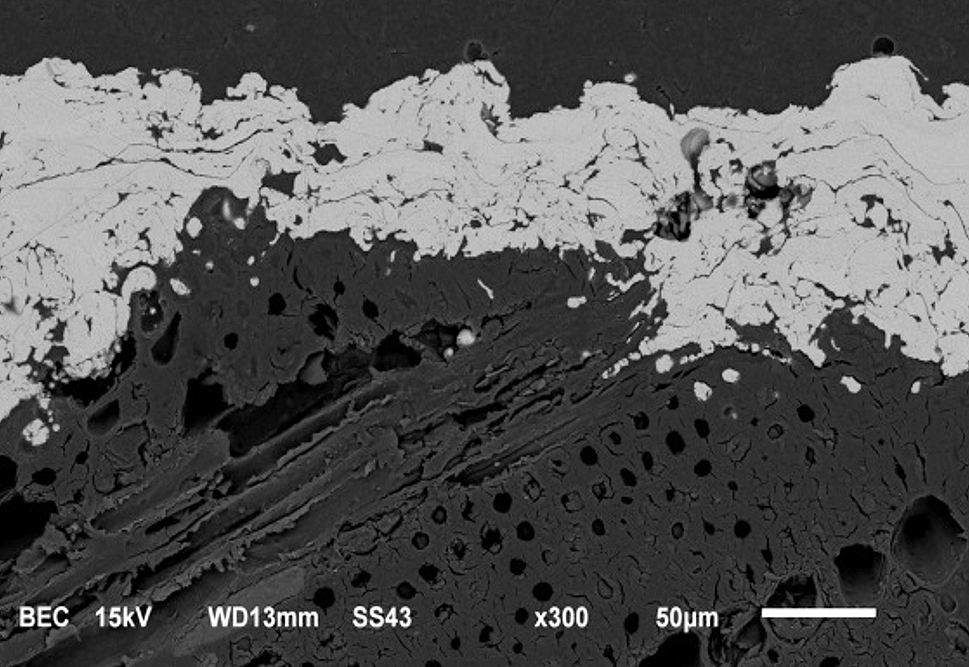

The adhesion of thermal sprayed coatings to wood is provided by mechanical interlocking of quickly solidified metal droplets into substrate asperities (Figure 2). Therefore, the adhesion of metal to wood is greatly influenced by wood surface morphology, which varies between wood species and can be enhanced by surface preparation techniques such as sanding.

Figure 2. SEM image of cross-section of a copper-coated mahogany wood sample

We measured the adhesion strengths of copper coatings to wood samples by a standard pull-off test (ASTM D4541) using 20 mm dollies. The dollies were glued onto the coated surfaces of wood samples and then pulled off using an adhesion tester (PosiTest AT-M, DeFelsko, NY, USA). The results for the adhesion of copper coatings to various wood samples are shown in Figure 3. Overall, the adhesion of the Cu coating to both hardwood and softwood species was very good. The values were lower than the wood tensile strength for oak, but higher than the wood strength for other samples.

Figure 3. (Left) copper coating adhesion test on MDF and mahogany wood. (Right) Adhesion strength of copper coating to different wood species .

The adhesion to MDF substrates was the lowest in comparison with solid woods. In this case, the coating adhesion was higher than the cohesion of bulk MDF (Figure 3). Overall, the adhesion of Cu-coatings to both hardwood and softwood wood species was very good. In some cases, the wood fibres were pulled with the coating, which indicates that the coating adhesion was comparable with the wood cohesion. For other very common substrate materials, like a glass-filled Nylon 6, a copper alloy of CuNiZn coating showed average adhesion of ~ 1300 psi.

Fire Resistant Features

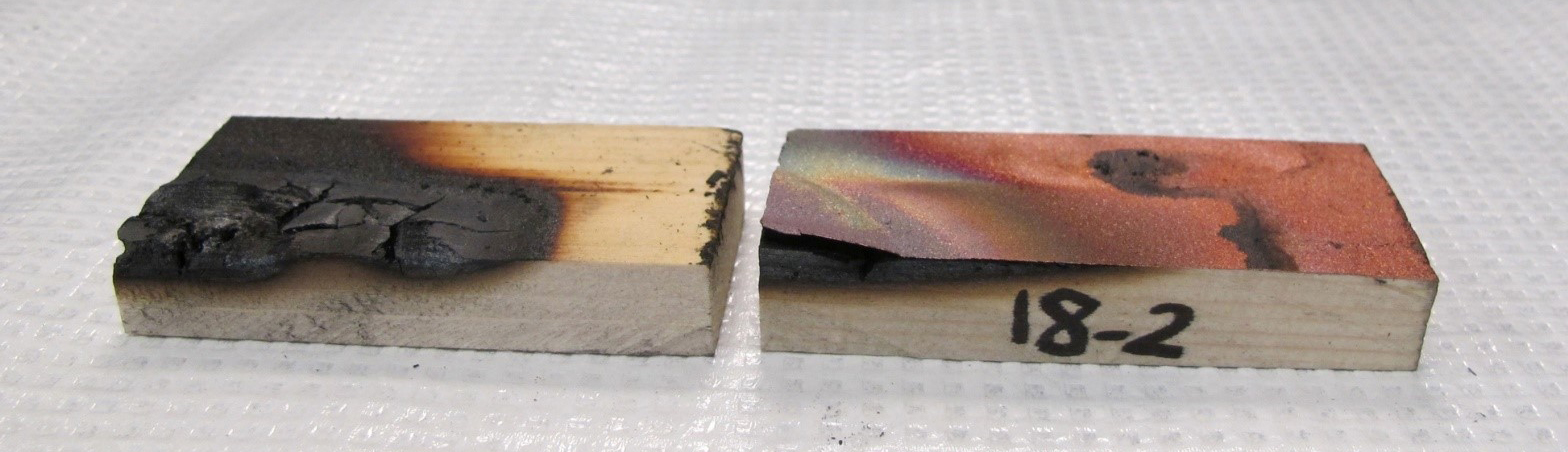

Metal coatings also offer additional advantage for organic substrates, such as better fire rating during fire tests according to ASTM D3806 (Figure 4).

Figure 4. Comparison of soft maple charring depth (left) without and (right) with copper coating

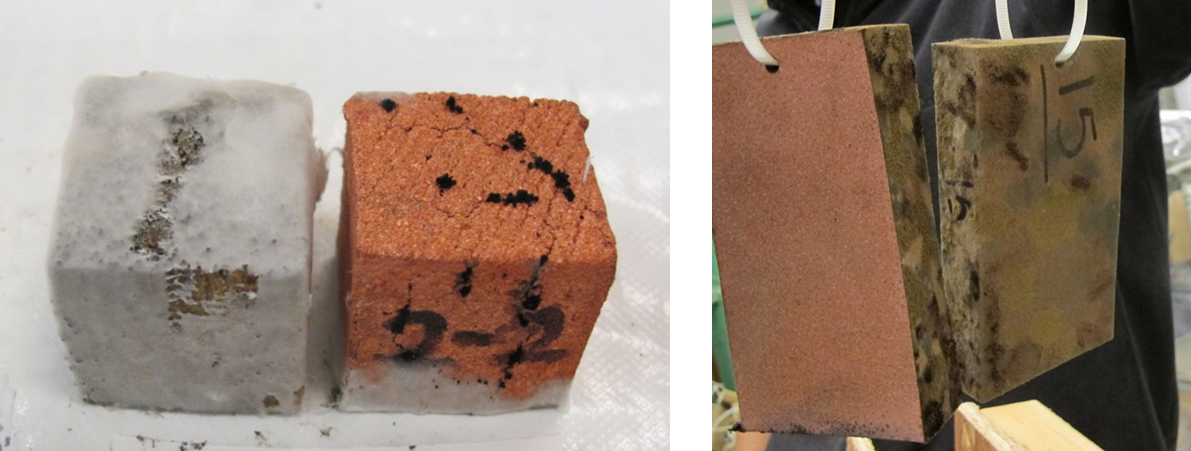

Fungi and Mildew Protection

Softwood species, such as pine and spruce, are usually treated with copper-based preservatives to protect them from decay and insects. Our copper alloy coatings are also able to protect the wood from moisture, ultraviolet (UV) light, fungi, and mildew. We studied the performance of these coatings on various wood species as well as MDF wood composite with respect to decay and mildew. The resistance of a Cu-coated sample to fungi and mildew growth was assessed based on the American wood preservation association’s standard test methods (AWPA E24-06 and E10-06). Figure 5 shows some of the results.

Figure 5. (Left) comparison of Pine wood with and without copper cpating after 12 weeks exposure to fungi. Average weight loss for the uncoated and Cu-coated samples were 55 ± 7% and 4 ± 3%, respectively. (Right) Coated and uncoated MDF samples after 8 weeks in conditioning chamber at 32°C and 95% humidity inoculated with 4 mold species.

References

1. Gutierrez, H., Portman, T., Pershin, V., and Ringuette, Evaluation of biocidal efficacy of copper alloy coatings in comparison with solid metal surfaces: generation of organic copper phosphate nanoflowers. J. Appl. Microbiol. 114: 680–687, (2013).

2. Grass, G., Rensing, C. and Solioz, Metallic copper as an antimicrobial surface. Appl Environ Microbiol 77, (2011) 1541–1547