Anti-Bacterial Coatings

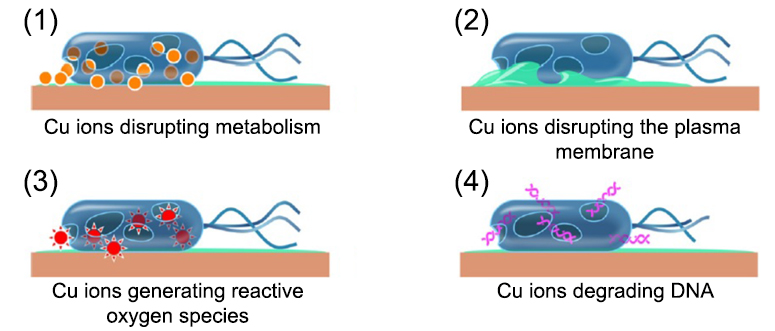

It has been known for centuries that silver and copper have antiseptic properties. There are several mechanisms proposed on how copper (more precisely Cu2+ and Cu+ ions) kills bacteria. It can be due to disrupting bacterial metabolism or plasma membrane by generation of reactive oxygen species and degrading bacterial DNA.

Copper and a large number of its alloys were certified as antimicrobial by the US Environmental Protection Agency (EPA). However solid silver or copper alloys are prohibitively expensive for uses for hospital furniture; also, there are challenges in manufacturing complex shapes from sheet metal. A cost effective solution can be to coat a very thin metal layer on frequently touched surfaces. Twin wire arc spray is well known as one of the less expensive thermal spraying processes capable of producing dense coatings at high deposition rates.

At CACT, we have developed a technique for deposition of copper alloy coatings with antibacterial properties on various substrates such as wood, plastic, or metal, using the twin wire arc process. These durable metal surfaces with long lasting antibacterial properties could provide a non-toxic, cost-effective, and eco-friendly way of countering bacterial contaminations in hospitals, nursing homes, and other public places.

Numerous biocidal studies by CACT, Department of Cells & Systems Biology, and University Health Network (UofT) were conducted for evaluation of such coatings, and the results were presented on conferences and published in journals. These results show that the coatings can kill bacteria within a few minutes of exposure.

Copper alloy coating on various touch surfaces in hospital, for a large project supported by the Grand Challenges Canada grant

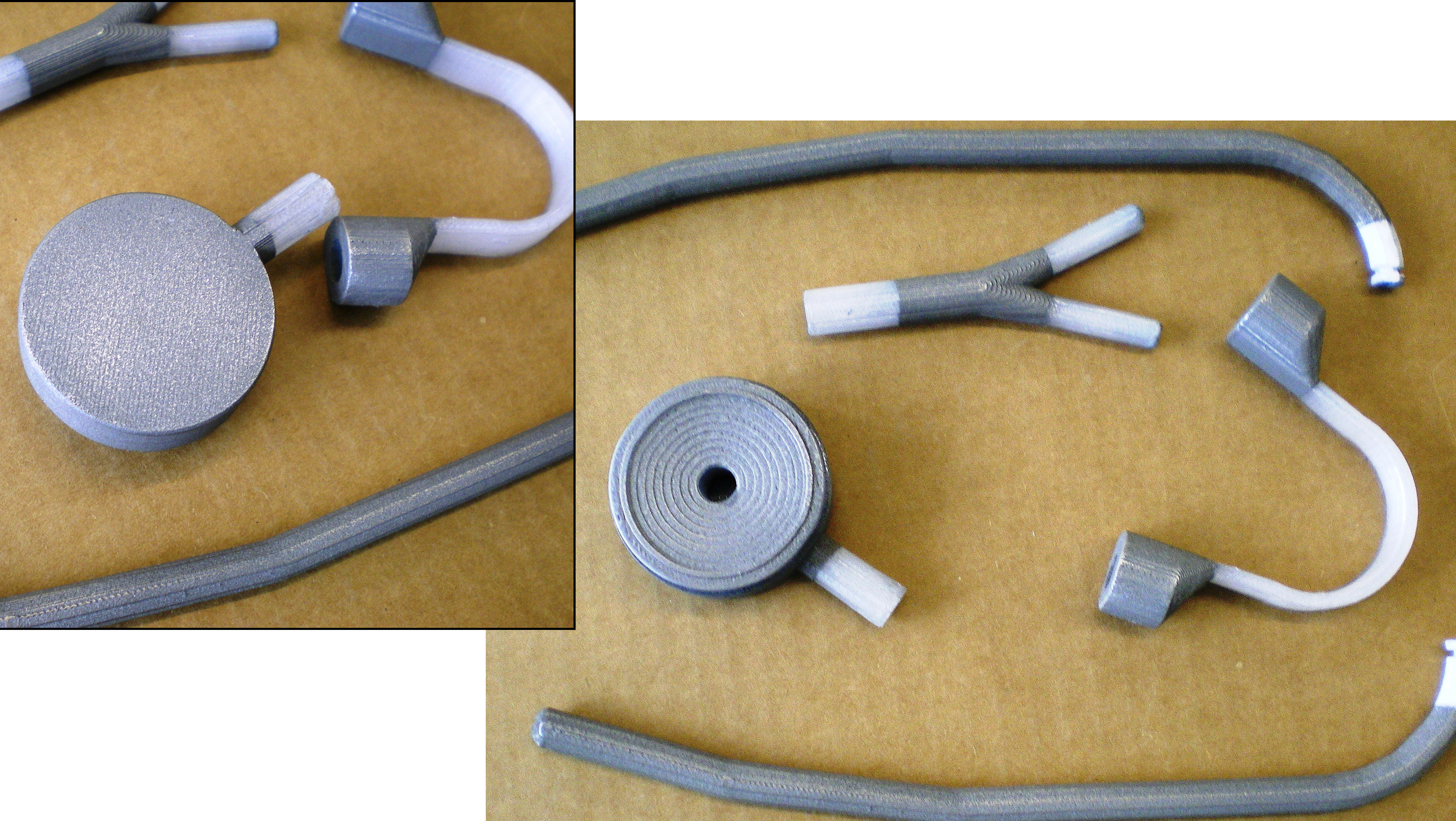

3D printed stethoscope, coated with copper alloy in CACT, as UofT initiative to help hospitals with PPE

A large project supported by the Grand Challenges Canada grant was concluded in 2015 with participation of two hospitals with significantly different environments, cleaning protocols, and bacterial loads. The participating hospitals were Mount Sinai Hospital in Toronto, Canada, and Universidad Peruana Cayetano Heredia, Instituto de Medicina Tropical Alexander von Humboldt in Lima, Perú. In May 2020, CACT also participated in the U of T’s Institutional Strategic Initiatives COVID-19 Response Resource project by coating 3D-printed medical equipment with copper alloy in an effort to help hospitals with personal protective equipment (PPE).

Anti-Microbial Mechanism

Copper ions are released when microbes are transfered by touching, sneezing, or aerosols and land on the copper surface. These ions prevent cell respiration, punch holes in the bacterial cell membrane or disrupt the viral coat, and destroy the DNA and RNA inside. Destruction of the RNA means that no mutation can occur – preventing the microbe from developing resistance to copper.

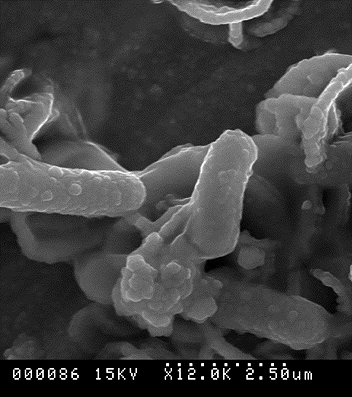

(a) deformed and compromised membrane

(b) dead bacteria

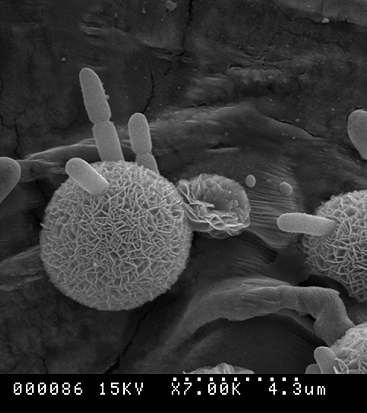

(c) nano structures formed from proteins of dead bacteria

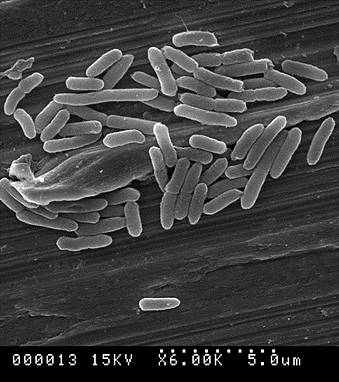

(d) bactria multiplies on stainless steel after 120 min

E-coli transformation on (a,b,c) copper alloy coatings in comparison with (d) stainless-steel surfaces

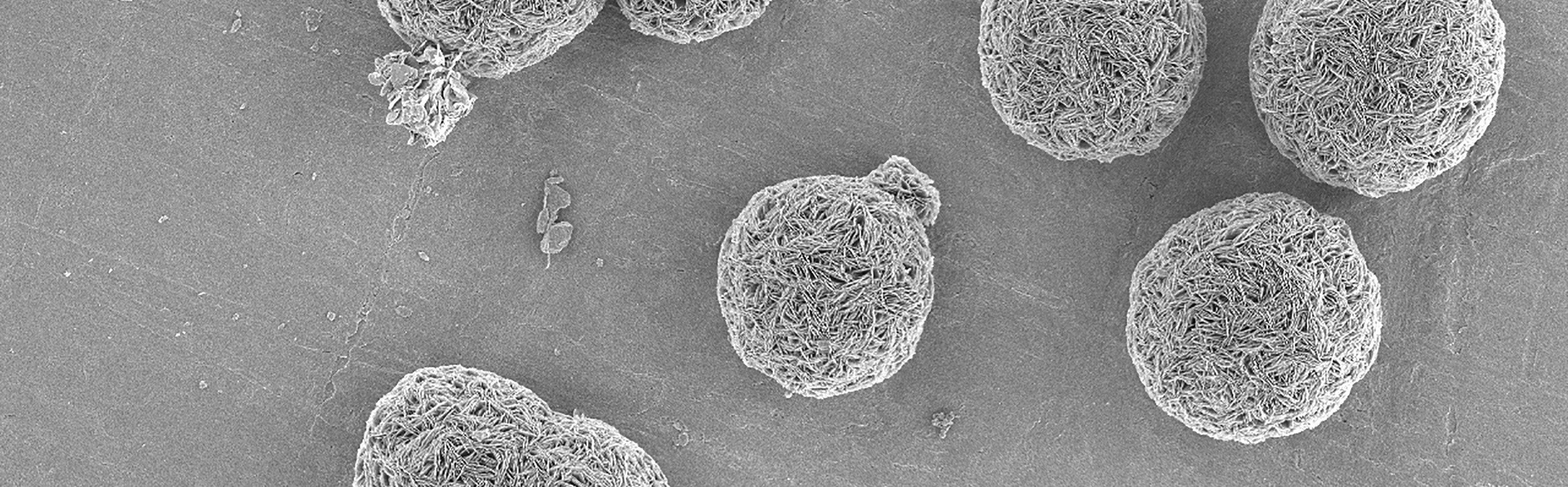

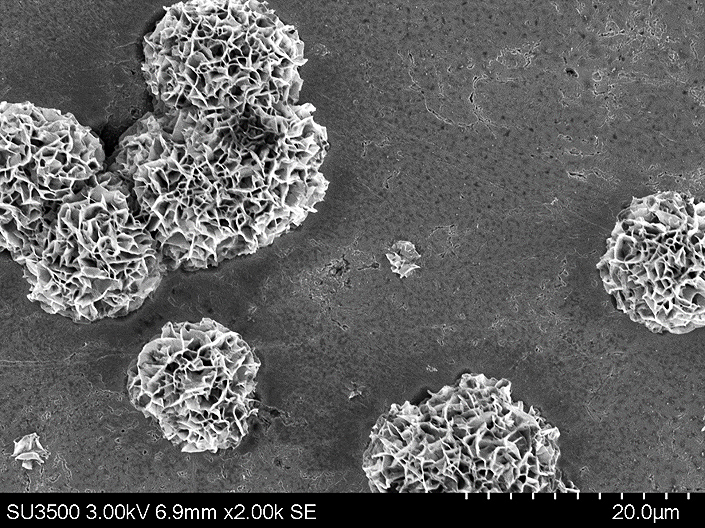

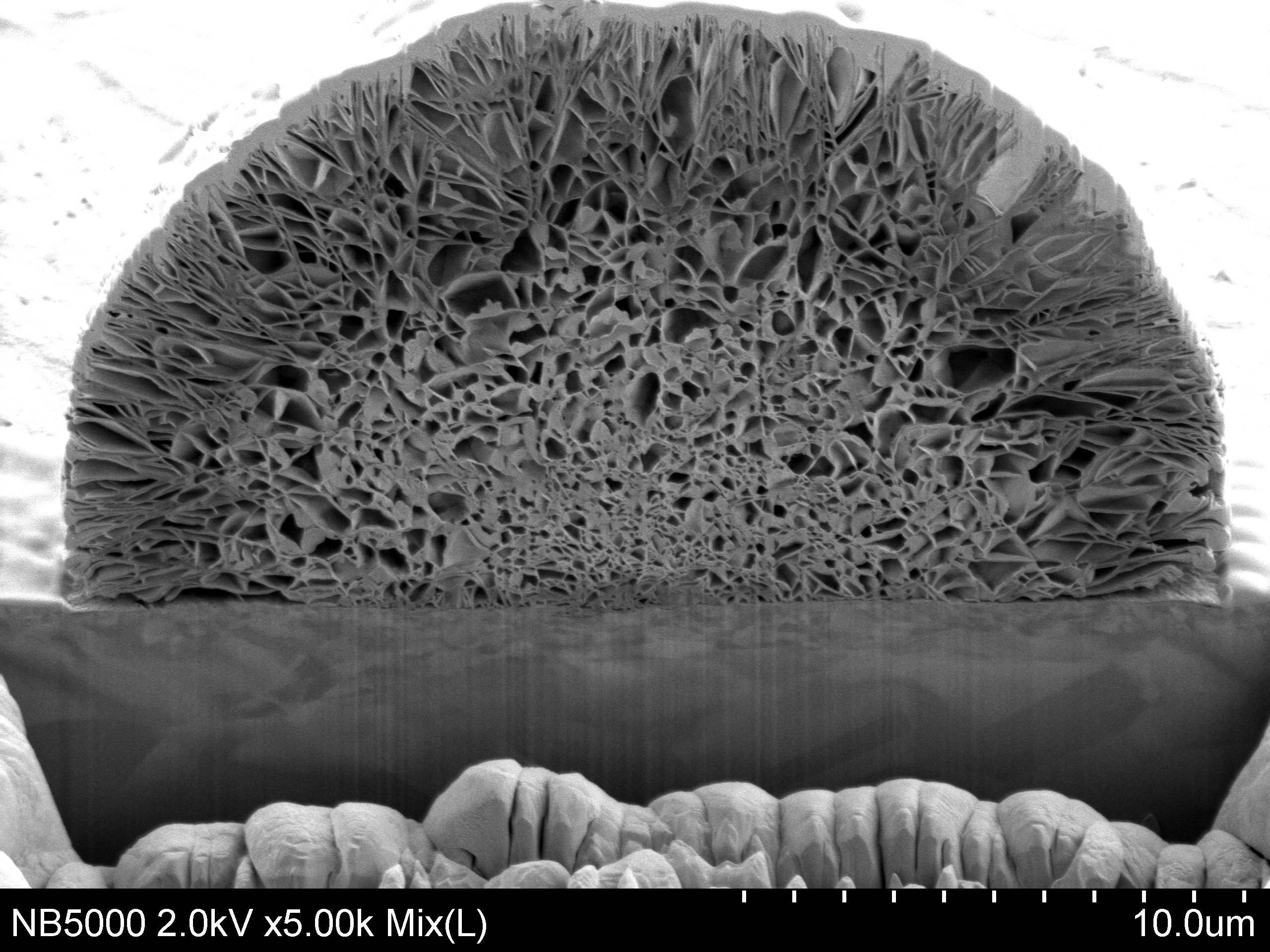

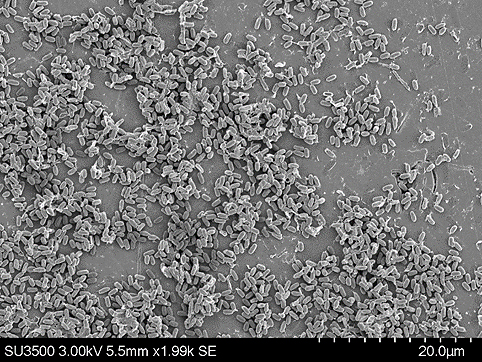

Our test results showed that exposure of spores to stainless steel for 7 days had no impact on their morphology. In contrast, the spores exposed to copper alloy appeared deformed after 2 hours. After a day of exposure, nanoflowers structures were visible. By day 7, the majority of spores degraded into nanostructures. These nanostructures are generated by binding of copper ions to a protein core, triggering the formation of copper phosphate crystals. Analyses indicated that they were enriched in copper (48.2%), oxygen (26.2%), and phosphorous (13.6%).

Spores turned into nanoflowers on copper alloy coating

A nanoflower sectioned with focused ion beam (FIB)

Condition of spores on stainless steel after 7 days